Surge protection in electrical installations is essential to ensure the safety and integrity of equipment and electrical systems. Surge Protection Devices (SPDs) play a crucial role in this process by diverting excessive energy caused by lightning strikes or other anomalies to the grounding system, thereby protecting the installation. This article provides a comprehensive guide to SPDs, covering their types, operation, relevant standards, and best installation practices.

What Are Surge Protection Devices (SPDs)?

SPDs are devices designed to protect electrical installations from voltage surges, which can be caused by phenomena such as lightning strikes or switching operations within the electrical network. These devices are connected between the phase and ground of the installation, diverting the surge to the grounding system and protecting the connected equipment.

Standards and Regulations

In the United States and the United Kingdom, the primary standard governing the installation and use of SPDs is the IEC 61643 series of international standards. These standards define guidelines for the protection of structures against lightning strikes and detail the requirements for SPD installation, including classification and positioning within the electrical system. For the UK, the BS EN 61643-11 is commonly referenced for low-voltage systems.

Classification of SPDs

SPDs are classified into different categories based on their capacity to withstand and dissipate surges:

- Type 1: Designed to protect against direct lightning strikes, these are robust and typically installed at the point of entry to the electrical installation.

- Type 2: Used for protection against indirect surges and switching overvoltages, they are frequently installed in distribution boards.

- Type 3: Provide additional protection and are installed close to sensitive equipment, such as electronic devices.

How SPDs Work

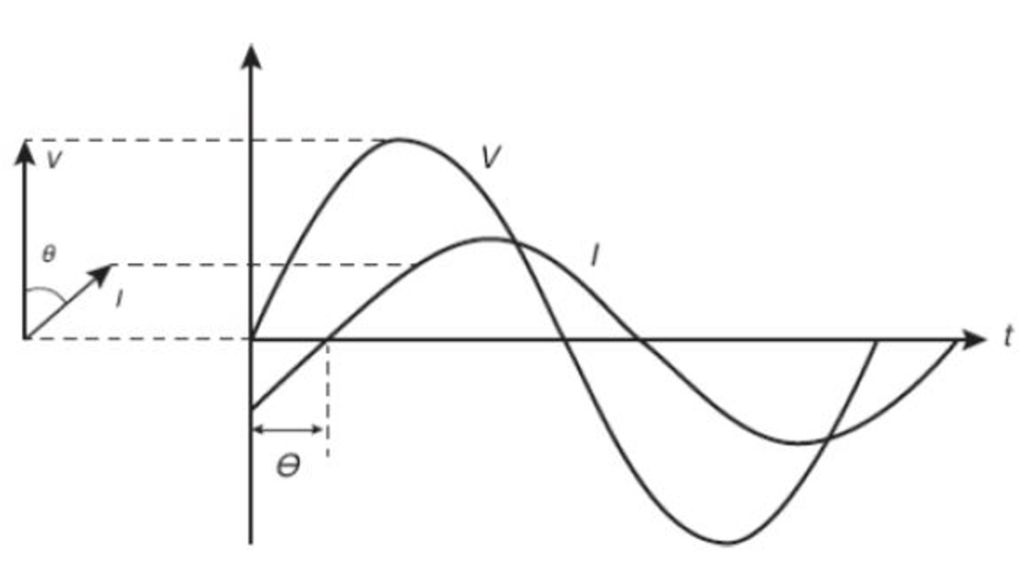

SPDs act as a kind of relief valve for excessive energy. Under normal conditions, they have high resistance, isolating the live conductors from the ground. When a surge occurs, the resistance of the SPD drops significantly, allowing the surge current to be diverted to the ground, preventing damage to equipment.

There are two main types of SPDs based on their electrical action:

- Short-circuiting: They abruptly reduce their resistance upon detecting a surge, directing it to the ground.

- Non-short-circuiting: They act as voltage limiters, gradually adjusting their impedance to divert the surge.

Types of SPDs by Technology

SPDs can be built using various technologies, each with specific characteristics:

- Spark Gaps: Use an electric arc to create a low-impedance path during a surge.

- Varistors: Resistors that change their resistance based on the applied voltage, they are quick and effective at dissipating surges.

- Suppression Diodes: Primarily used in Type 3 devices, these rely on Zener diodes to limit voltage.

Installation Topologies

The installation of SPDs must follow specific topologies, such as the TN-S and TN-C systems, to ensure the surge is effectively diverted to the ground. Additionally, it is common to use fuses in series with the SPD to add an extra layer of protection.

Lightning Protection Zones (LPZ)

Electrical installations are divided into Lightning Protection Zones (LPZ), which vary depending on the severity of the surges that may occur. SPDs are installed at the boundaries of these zones:

- Type 1: Between zones LPZ0B and LPZ1.

- Type 2: Between zones LPZ1 and LPZ2.

- Type 3: Between zones LPZ2 and LPZ3.

Best Practices for Installing SPDs

- Selecting the Right SPD: Choose the appropriate SPD based on the classification of the installation and the required levels of protection.

- Proper Installation: Follow standards such as IEC 61643 and ensure the SPD is correctly positioned and has effective grounding.

- Regular Maintenance: Regularly inspect SPDs, especially Type 3 devices, to ensure they are in good working condition.

FAQ about Surge Protection in Electrical Installations

- What is an SPD and why is it important? An SPD (Surge Protection Device) is a device that protects electrical installations from voltage surges by diverting excess energy to the ground. It is essential to prevent damage to equipment and avoid system failures.

- How do I choose the right SPD for my installation? The choice of SPD depends on the installation’s location, the type of protection needed (direct or indirect), and the sensitivity of the equipment to be protected. Refer to SPD classifications (Type 1, 2, 3) and standards such as IEC 61643 to make the correct choice.

- Where should SPDs be installed? SPDs should be installed at energy entry points, in distribution boards, and near sensitive equipment depending on the type of SPD. It is recommended to follow the TN-S or TN-C topology for optimal protection effectiveness.

- How often should SPDs be inspected? SPDs should be inspected regularly, especially after known surge events such as storms. Type 3 SPDs require more frequent checks, as failures in these may not be immediately noticeable.

- Can an SPD fail? Yes, SPDs can fail, especially after they have exhausted their energy dissipation capacity. It is crucial to monitor their condition and replace damaged units to maintain effective protection.

- What are the types of SPDs? SPDs can be classified as:

- Non-short-circuiting: Composed of nonlinear resistance-based or discharge-type arresters.

- Short-circuiting: Which directly act in a short circuit but are not recommended in all situations.

- Non-short-circuiting: Composed of nonlinear resistance-based or discharge-type arresters.

- When is the use of an SPD mandatory? The mandatory use of SPDs is specified by standards like IEC 62305 (and the corresponding parts in UK and US standards) in areas with a high incidence of lightning or where sensitive equipment must be protected.

- How should SPDs be connected to ground? The grounding terminal of SPDs should be connected to one of the following:

- A linked system including all metallic masses of the installation and any conductive elements outside the installation.

- An independent grounding electrode with appropriate resistance to handle fault currents.

- A linked system including all metallic masses of the installation and any conductive elements outside the installation.

- What precautions should be taken when connecting conductors to the SPD? The conductors connecting the SPD to the live conductors and the ground should:

- Be sized to handle the maximum currents that may pass through the SPD.

- Have cross-sectional areas according to protection conductor requirements.

- Be adequately insulated, equivalent to the installation conductors.

- Be sized to handle the maximum currents that may pass through the SPD.

- What is the difference between TN-C, TN-S, TT, and IT grounding systems? These systems refer to the configuration of neutral and protective conductors:

- TN-C: Neutral and protective conductors are combined into one conductor (PEN).

- TN-S: Neutral and protective conductors are separate.

- TT: Neutral and protective conductors are separately grounded.

- IT: Isolated ground system with a grounding point through high impedance.

- How do I choose the appropriate SPD for my installation? The selection of the correct SPD should consider nominal current, maximum residual voltage, and the required protection level. It is also important to take into account environmental conditions, such as exposure to lightning, to determine the need for a higher current capacity SPD.

- Why is installing SPDs in a building important? Installing SPDs is crucial for protecting electrical and electronic equipment from damage caused by transient overvoltages. This enhances the safety of the installation, prevents financial losses due to equipment failures, and ensures the continuous operation of critical systems.

If you liked this article, consider sharing it on social media, this will help to spread knowledge, leave your comment below so we can know your opinion.